Introduced at CES 2017, the Metal X 3D printer debuted as a revolutionary system that enables safe and efficient desktop metal additive manufacturing. At the time of release, Mark commented, “If you can afford a half million to million dollar metal printer, buy one. For the rest of the world, this is for you.”

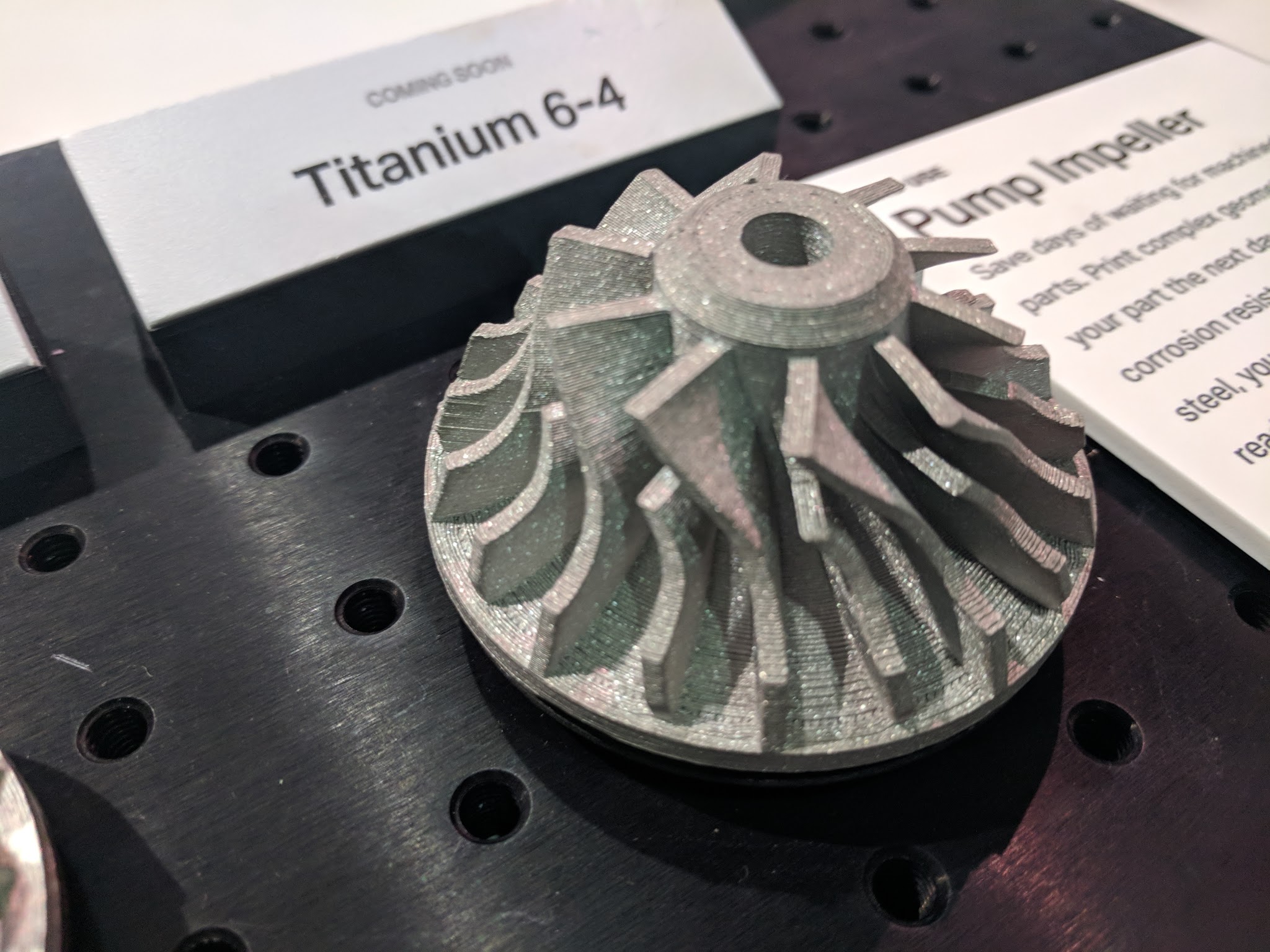

The Metal X can process a wide range of metal materials, some that are not included in established industrial machines. This includes, 17-4 Stainless Steel, 303 Stainless Steel, 6061 Aluminum (Beta), 7075 Aluminum (Beta), A-2 Tool Steel (Beta), D-2 Tool Steel (Beta), IN Alloy (Inconel) 625 (Beta) and Titanium Ti-6Al-4V (Beta).

Markforged officially shipped the first batch of its Metal X systems to customers around the globe in April. Following this, industrial tooling and household hardware manufacturer Stanley Black & Decker became the first company to install a full Metal X system – the 3D printer, a Sinter-1 module and the Wash-1 for post-processing.

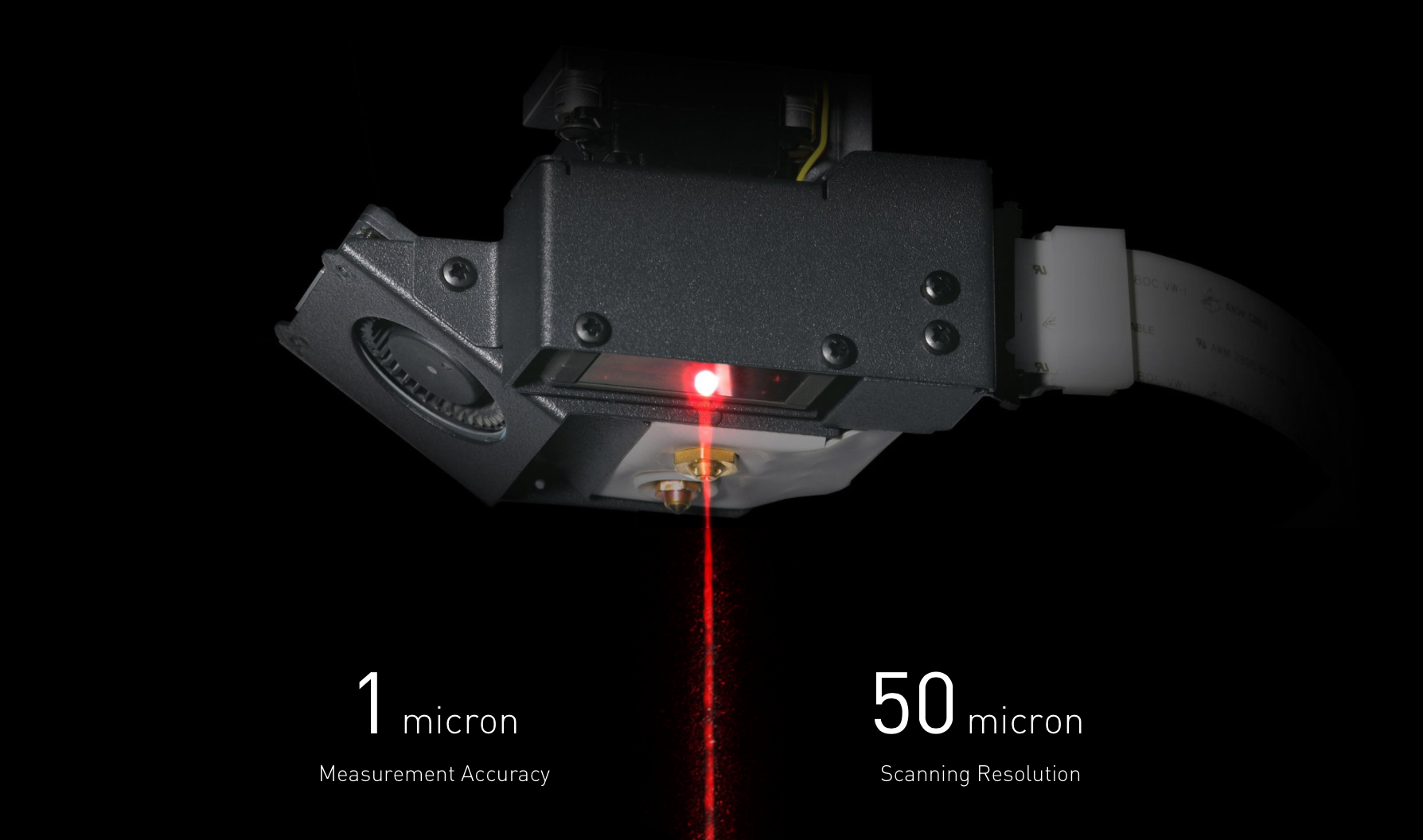

The Metal X uses Markforged’s proprietary Atomic Diffusion Additive Manufacturing (ADAM) technology. This process combines metal powder with a binder which is then extruded onto a print bed, similar to FFF additive manufacturing. When complete, the part is sintered in a kiln and washed to rid of unwanted residues.

The Metal Monday offer extends to all US orders received on or by December 17, and all UK and EU orders received on or by December 11.

Keep up with the latest 3D printing by subscribing to our free newsletter. Also, follow us on Twitter and like us on Facebook.

To commence your career in additive manufacturing or post new opportunities, join 3D Printing Jobs.

Featured image shows the Metal X 3D printer from Markforged. Photo via Markforged.

Tia Vialva

Tia holds a BA in journalism, and has a background in writing news and features.