Following its announcement of “Metal Monday” end of year 3D printer sales, Boston manufacturer Markforgedis set for a strong close to 2018 with the launch of H13 material.

A hot work tool steel, the H13 filament is made for use on the Markforged “desktop-sized” Metal X 3D printer. The material is ideal for making molds for plastic injection, as such Jon Reilly, Markforged VP of product, is calling H13 “a game changer” for manufacturers of high-volume plastic parts.

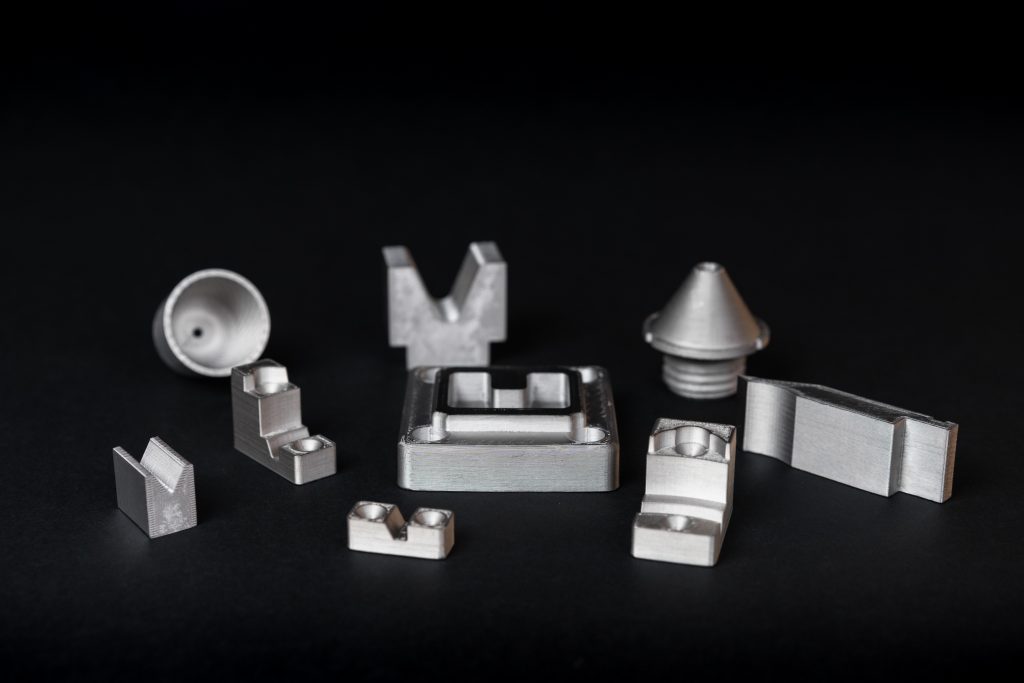

H13 tool steel

In traditional manufacturing, H13 is an incredibly versatile and widely used tool steel. As a material, it exhibits excellent red hardness, making it resistant to thermal cracking when worked at elevated temperatures, and high toughness.

In Germany and Japan H13 is also traded as s EN 1.2344 and SKD61. Sample applications of the material include engineering inserts, cores, and dies that, in addition to toughness, have a high-polish finish.

Though Markforged is not the only metal desktop 3D printer company to use this material, H13’s compatibility with the Metal X does open up new markets and potential uses for its customers.

3D printing brings innovation to injection molding

California based company Grant Engineering is one of the Metal X’s early adopters. Its core business is 24-hour injection-molded plastic parts production. According to Randy Grant, co-founder and co-owner of Grant Engineering, “Much like the robots and automation we’ve already introduced into our workflow, we see 3D printing – especially the Metal X – as a way keep us hyper-competitive on cost and turnaround time while still delivering the precision and quality we’re known for,”

“Being able to 3D print H13,” he adds, “should enable a lot of innovation with injection molding. We can’t wait.”

Already, Grant Engineering has been using the Metal X to 3D print 17-4 PH stainless steel molds for production. The H18 will be a step forward for such applications at the company.

Award winning 3D printing

Markforged began shipping its compact Metal X system in April 2018. Seven months later, the company celebrated the completion of 100 successful shipments of the machine.

For two years in a row the Metal X’s elder brother, the Mark Two carbon fiber 3D printer, has won Enterprise 3D printer of the year in the 3D Printing Industry Awards – perhaps 2019 will be the year of the Metal X?

Reilly adds, “We designed the Metal X system to change the way things are made,”

“THE LAUNCH OF H13 IS THE NEXT STEP DOWN THAT PATH.”

Make your nominations for Enterprise 3D printer of the Year and more in the 2019 3D Printing Industry Awards now.

For all the latest 3D printing news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Budding engineer? Join 3D Printing Jobs now for new opportunities in this rapidly growing industry.

Featured image shows Markforged H13 tool steel. Photo via Markforged