Proven Digital Manufacturing Capabilities

Our digital manufacturing solutions use traditional and additive processes to efficiently bring products to life. We work with you, side by side, to understand your goals and deliver parts that are on time, on budget, and perform as required, from prototype to full-scale production.

Rapid Prototyping

We use the best of traditional manufacturing methods and advanced 3D printing capabilities to deliver high-quality, functional prototypes that shorten cycle times and create better long-term manufacturing results.

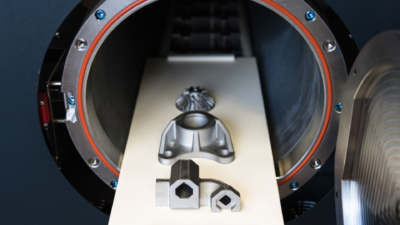

Learn More Additive Manufacturing

We combine cutting-edge 3D printing technology with advanced materials, design, and production expertise to develop additive solutions that deliver precision, speed, and better outcomes.

Learn More CNC Machining

We specialize in delivering precision-machined components, weldments, and assemblies for different stages of prototyping and end-use applications with top-level speed, accuracy, finish, and durability.

Learn More Sheet Metal Fabrication

We fabricate accurate, durable sheet metal parts, weldments, and assemblies in a range of prototype-to-production quantities, as well as production tooling, progressive dies, and fixtures for higher volumes.

Learn More Injection Molding & Tooling

We provide rapid, quick-turn injection mold tooling for fast, low-volume projects , as well as custom tooling for complex, higher-volume production runs in a wide range of thermoplastics and elastomeric materials.

Learn More Post Processing & Finishing

We offer a comprehensive suite of finishing and post-processing services, from part dyeing to a variety of surface textures, for best-in-class finished products that simply outperform competitor’s parts.

Learn More Not sure what you’re looking for?

The UPTIVE team is here to provide recommendations and insights throughout the process so you can understand your options and make the best decision.