How Additive Manufacturing Works

From rapid prototyping to high-volume production, additive manufacturing (3D printing) is a disruptive manufacturing technology that requires no tooling, can produce parts in a matter of days, offers design freedom and mass customization capabilities, as well as much more. With the advancement of disruptive 3D printing technologies, we can help your product team make changes during production without incurring delays or tooling modifications. Additionally, additive material and equipment technologies have evolved into a viable solution for at-scale production, achieving manufacturing production improvements that aren’t possible with traditional methods.

Our Additive Manufacturing Capabilities

For any stage and at any scale, we’re the strategic supply chain partner you can count on to deliver precision, quality, and repeatability. Our advanced 3D printing solutions for manufacturing leverage a wide range of technologies and expertise to increase your speed to market and drive efficiency at scale.

Fused Deposition Modeling (FDM)

HP Multi Jet Fusion (MJF)

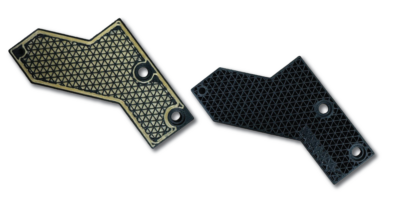

Selective Laser Sintering (SLS)

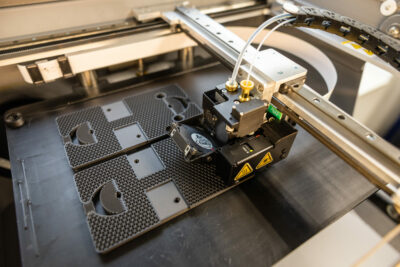

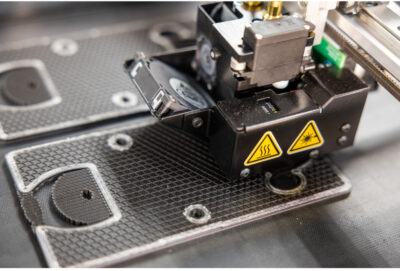

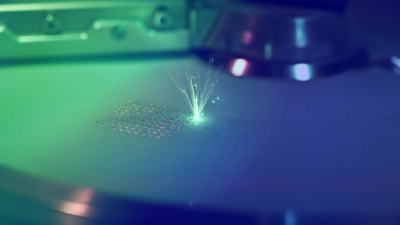

Direct Metal Laser Sintering (DMLS)

Additive Manufacturing Processes Comparison

| Process | Materials | Ideal for | Finishes | Max Part Size/Volume | Min Feature Size | Tolerance | Min Lead Time |

|---|---|---|---|---|---|---|---|

| HP Multi Fusion (MJF) | PA12, PA12G, PP, TPU, TPA, PA11 | Functional prototypes, end use parts, customized applications, jigs+fixtures, end of arm tooling | Vapor smoothing, dyeing, painting, coating, inserts, texturing, machining | 380mm x 284mm x 380mm | 0.3mm XY 0.5mm Z | +/- 0.2mm | As little as One Day |

| Fused Deposition Modeling (FDM) | ABS, ESD7, ABS, M30, ASA, Nylon 12CF, Nylon Black, PC, Ultem 1010, Ultem 9085 | Cost effective prototyping, manufacturing tools, colorized parts, educational models, replacement parts | Sanding, vapor smoothing, painting, tumbling, hydro dipping, inserts | 915mm x 610mm x 915mm | 0.5mm XY 0.5mm Z | +/- 0.127mm | As little as Two Days |

| Selective Laser Sintering (SLS) | Nylon White, TPU-PA12, Alumide, Nylon CF | Low volume production, tooling aids, medical applications, housings and ducting | Vapor smoothing, dyeing, painting, coatings, sanding/polishing | 500mm x 500mm x 500mm | 0.1mm XY 0.1mm Z | +/- 0.1mm for first 100mm | 3 Days |

| Direct Metal Laser Sinterding (DMLS) | AM Aluminum 6061, AM ALSi10Mg, AM Inconel 625, SS 17-4, SS 316L, Cobalt Chrome, Maraging Steel, Titanium | Aerospace, structural components, medical, surgical instruments, tooling, high-strenght light weight uses | Bead blasting, machining, sanding/polishing, anodizing, heat treating | 250mm x 250mm x 250mm | 0.1mm XY 0.1mm Z | +/-0.1mm for first 25mm | 10 Days |

Multi Jet Fusion (MJD) Design Guide

Multi Jet Fusion (MJF) is a revolutionary HP additive technology that enables you to quickly print complex and intricate parts. Download this design guide to learn more about HP MJF manufacturing options.

Why Customers Choose UPTIVE

Latest Insights

Composite Materials in Additive Manufacturing

The Advantages and Considerations of FDM

The Power of 3D Printing in Metal Part Replacement