Our Material Capabilities

We offer extensive material options and expert advice to help guide you through every stage of the production process.

Metals

Polymers

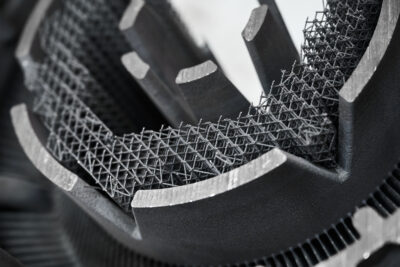

Composites

Not sure what you’re looking for?

The UPTIVE team is here to provide recommendations and insights throughout the process so you can understand your options and make the best decision. Questions? Call us at (888) 467-7686.

You can also view a full list of material spec sheets here.

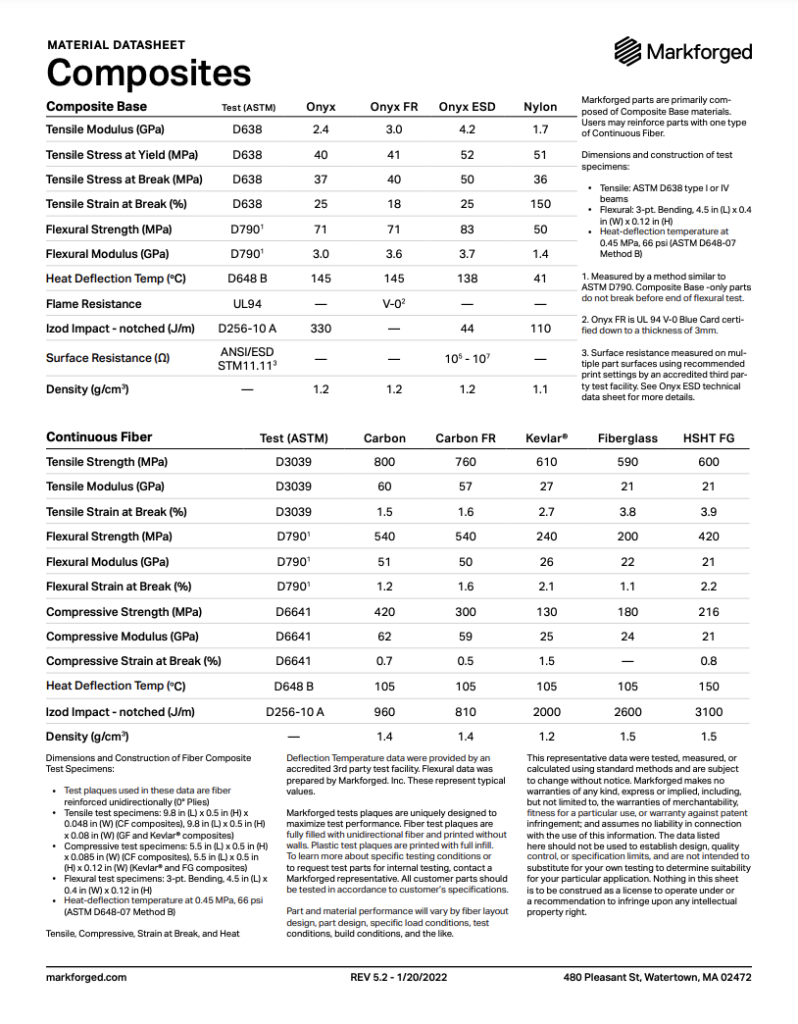

MarkForged Composites Material Design Guide

These guides serve as recommendations and may not reflect all implementations, since 3D printing is a geometry dependent process.

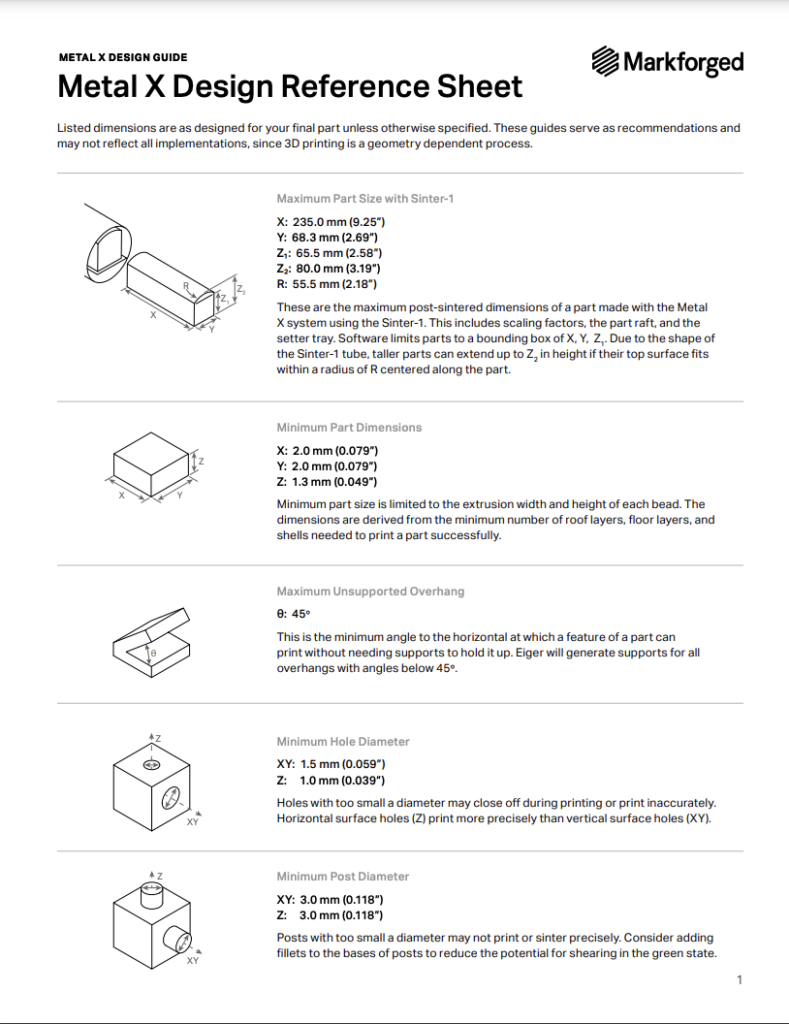

MarkForged Metal X Design Guide

These guides serve as recommendations and may not reflect all implementations, since 3D printing is a geometry dependent process.